There are two main ways to screen print a photographic image.

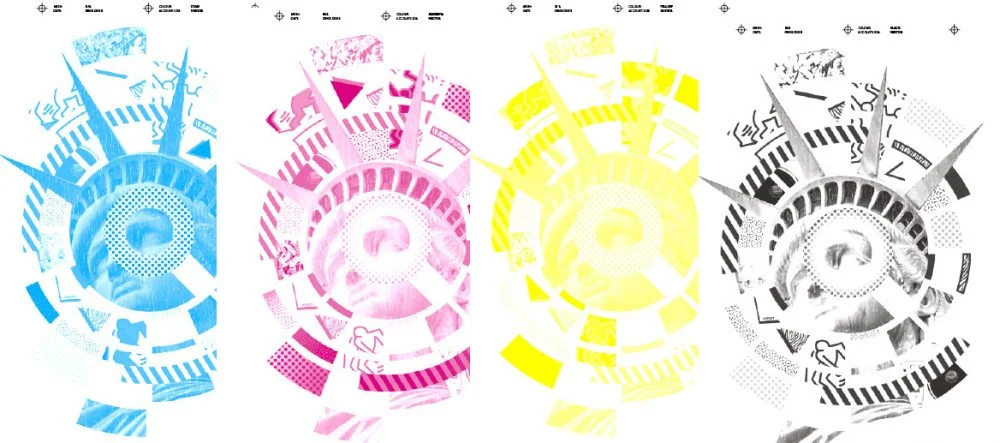

There’s the Simulation Process, and then there’s the Full-Colour (CMYK) Process.

The basic idea behind screen printing involves the use of screen stencils. These screen stencils can either be made from spot color or the full-colour process. Each colour is represented by an individual screen . Process colour printing is always four colours. Cyan, Magenta, Yellow and Black. Simulated process or spot colour printing can be many more colours. Both are printed using tiny dots lined up in exact registration to simulate the image. These dots are called half tone dots.

Full-colour process or CMYK inks (cyan, magenta, yellow, and black) are used as the industry standard for paper printing, but not often for printing t-shirts. The reason is, it only works on white t-shirts. The inks for CMYK printing are translucent, and the light passes through each to the white shirt on the bottom and then reflects back to the eye. If the shirt is coloured, it changes what you see. Sometimes it can work to print white ink underneath, but the nature of screen print causes the CMYK print to look muted or washed out when printed on white ink. So generally, CMYK printing is not a common process for printing on clothing.

The simulation process involves using opaque inks in solid colours and mashing them together on the press to create different colours and blends. When printing this way it works well with a white under layer, plus it is possible to use the colour of shirt as part of the formula. Complex computer software can make these colour separations taking into account the shirt colour and give the printer a good start with how it should be printed. Once the software finishes it’s part, it is up to the printer to adjust the separated colours in order to make a good simulation of the image. Simulated process often tends to be a lot of colours to create a good image. Eight, ten or even twelve colours is normal.

Types of Screen Printing and Their Applications

Plastisol Ink Printing provides durable, sit on top of the fabric providing a more vivid colour, results in a less soft hand, and requires curing at a temperature of 270 to 320 degrees F. Another advantage is that they don’t dry in the screen, are very opaque on darker coloured garments, and adhere to most textiles.

Discharge Ink Printing is growing in popularity. Discharge inks remove the shirt’s dye (somewhat like bleach) and replace the color, instead of printing colour on top of the shirt. This solution makes use of water-based inks and results in a softer feel and the look has a vintage style that customers love.

Vintage and distressed printing give you a similar effect as distressed jeans. It’s a real classic. With t-shirts, it’s pretty cool and has that by-gone era look or an authentic feel. People pay extra for this effect. The less amount of ink laid down on the garment provides a softer feel. Breaks in the ink layer make for a more flexible print, and the fabric itself is more breathable.

A Couple of Application Examples

Custom t-shirts are GetBold’s specialty. We see great results from our work on a regular basis. Whether your goal is to represent your business, your team, your school, or just want something fun, GetBold will help you get there. We have some great ideas to inspire you right here in our showroom. And we know just the right printing technique that is most appropriate for your design.

Custom jackets can make a real statement. And it is a great way to ensure that your message is not covered over by employees wearing layers of cloths. Whether you need custom company identity to promote your brand or a team-look in colder weather, GetBold has a wide variety to choose from.

GetBold When It Comes to Custom Designed Apparel

At GetBold, we are definitely in the people business. Our expert apparel printers maintain a sense of pride in our work. We know that you, our customer, will benefit not only from our expertise but also from our attitudes.